The X Series Reach Stacker with a 99,000lb load capacity, is built for the rugged environments that ports and container terminals are known for. The reach stacker is based on the same chassis that our heavy duty X Series forklifts use. Because of this, the X Series Reach Stacker inherits the same design characteristics that make the X Series Pneumatic Forklifts safe, reliable, comfortable, and efficient. The new X Series Reach Stacker loads, handles, and stacks 20’ and 40’ ISO heavy containers and meets the requirements for high-intensity and long-term operations of containers at ports, docks, railway and highway transfer stations, storage yards, etc.

The fully enclosed, floating cabin has a curved front window and redesigned sides to increase visibility. The cabin doors are all glass to increase visibility beside the forklift. The exterior design of the whole vehicle is at the forefront of the development of forklift design. While sturdy and elegant in appearance, the vehicle remains practical and rugged. The integrated interior design is simple and comfortable to improve productivity and keep the operator focused.

The X Series Reach Stacker was designed with performance in mind. The Reach Stacker features a newly designed cab, wet disc brake drive axle, easy-to-read instrument display, and highly efficient LED lights as a part of the standard configuration. The Reach Stacker also features American PARKER’s combined hydraulic valves, Danish DANFOSS’s variable hydraulic pump, and a load sensing hydraulic system to reduce the continuous load of the engine and increase performance.

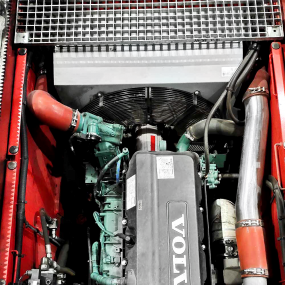

The X Series Reach Stacker features fans with electronic motors that are used independently to cool hydraulic oil and brake oil. The torque converter oil temperature control management ensures that the gearbox works within the optimal temperature range. The large radiators and suction fans are also a part of the design. All of these features are included so that the reach stacker can reliably operate in up to 122F temperatures.

The new floating cabin is designed to promote comfort and safety for the operator. The cab offers a waterproof and dustproof design to keep the operator out of the elements. The cab also designed to reduce the noise coming in the cabin. The air conditioner has been redesigned to enable better performance and more uniform cabin cooling. The interior features molded components to provide the operator with a more comfortable and ergonomic operating environment. The cab also features a new integral frame made up of steel to increase strength and safety. Finally, the cab and the forklift’s profile have been optimized to increase visibility and enable the operator to see all around the truck.

The ergonomic integral joystick enables accurate control of the forklift. The optimized hydraulic braking system enables smooth, easy-to-control, braking. The suspension seat and adjustable armrest allow for the operator to find their ideal driving position. Together all of these features create a more comfortable operating experience for the operator.

The newly designed instrument display offers more comprehensive functions and more stable performance. It displays important information on the truck’s status as well as engine faults. The battery compartment provides easy and convenient access to the battery. The optional electric tilting cabin allows the cabin to be tilted without any tools. This allows for easy accessibility of major components and quick and easy maintenance. This design creates less downtime.

Hangcha uses the powerful Volvo diesel engine in the X Series Empty Container Handler. The Volvo engine is Tier 4F compliant. This engine helps Hangcha’s X Series Empty Container Handler maximize its efficiency and reliability for the end-user.

The DANA 36000 transmission provides stable, accurate, and reliable travel with its power shifting feature.

The forklift features a KESSLER heavy-duty drive axle, two-speed deceleration, wet brakes, and hydraulic release spring action parking brake for safe and reliable operation.

- The next generation ELME817 series telescopic container spreader is used on Hangcha’s X Series Reach Stacker. The design of the telescopic beam, turntable, etc. are optimized, so that the structural strength is increased, the weight of the spreader is 16% less than that of the spreader of the last generation and the service life is prolonged by 30%.

- The arrangement of the next generation ELME817 series telescopic container spreader’s oil cylinder is changed to be more conducive to maintenance.

- Design of the hydraulic system is optimized, so that the spreader system has less pressure loss and is more energy-saving and efficient.

- With electro-hydraulic proportional control, the speed is adjustable and the rotation angle of the spreader can be controlled smooth and acurately.

- The twist-lock interlock device (mechanical and electro-hydraulic) and the real-time indication of the action indicator are provided to avoid the container being lifted when less than 4 corners are locked.

- The lift interrupter can prevent the container from being lifted when the twist-lock is partly twisted. The lift operations can be performed only when the twist-lock is locked or

unlocked..

- Customized Color

- Solid Pneumatic Tires

- Fire Extinguisher (4.4lb/8.7lb)

- Automatic Fire Extinguishing Device

- Blue Light

- Front Camera (with optional memory)

- Twist-Lock Camera

- Video Recording System

- Scale

- Ground Strap

- Tire Pressure Monitoring System

- Block Heater